Bringing Fans Closer to the Action: Swiss Sports Channel, MySports, Broadcasts Switzerland’s National League Hockey with Haivision Pro Mobile Video Transmitters

MySports, a sports channel owned by Swiss telecom company Sunrise, specializes in broadcasting ice hockey, including all games of the Switzerland’s National League games and other premier international ice hockey matchups.

Lang Baranday, a Haivision partner in Switzerland, provides innovative technology and services to broadcasters and video professionals.

The Swiss National League is made up of 14 teams who each play 52 games in a season, in venues across Switzerland. MySports wanted to deliver unparalleled live coverage from these venues to enhance the audience’s viewing experience. To do this, they decided to move their broadcast production from the OB Truck outside the venues and bring the broadcast production and on-air talent into the arena and right next to the action taking place on the ice.

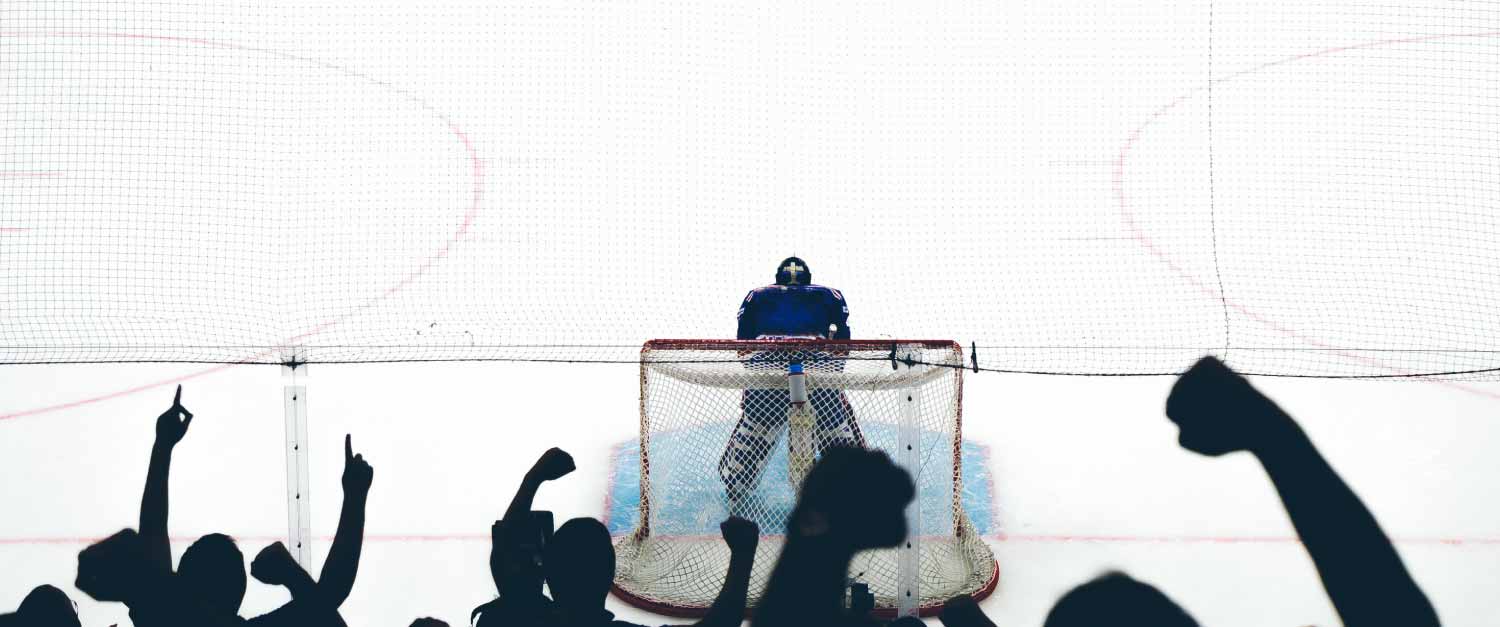

For National League games, we’ve decided to take our studio programs out of the traditional setting and bring them directly to the arenas, where we set up rink-side broadcast studios. By being in the arena and out in the open with the fans and the action, we aimed to capture the vibrant atmosphere of live hockey like never before. This new approach would allow us to provide dynamic and immersive coverage that resonates with viewers,” says Simon Hess, Team Leader MCR/Playout at MySports.

To achieve the goal of providing more immersive coverage from numerous arenas across Switzerland, they needed to adopt remote production technology to connect the broadcast studio and the master control room (MCR) in Erlenbach with the onsite teams at the venues. This remote production workflow enabled them to deliver high-quality broadcasts while reducing the logistical challenges of larger, complex on-site setups.

Lang Baranday worked closely with MySports on their workflow for the new broadcast productions at the arenas. They were looking for broadcast contribution transmitters that provided the best combination of video quality, latency, reliability and flexibility. They tested several products over 5G networks, including Haivision’s low-latency live video transmitters, to find the ideal solution to meet their unique requirements of broadcasting live from the hockey arenas.

“To make this vision a reality, we rigorously tested different providers and ultimately chose the Haivision Pro460 mobile video transmitter together with the StreamHub receiver. It was the most effective, with the highest performance. Now, the remote production setup includes a studio with two cameras at the venue that send live content to the StreamHub receiver located in the MCR in Erlenbach. This workflow ensures we can capture all the excitement and key moments from the heart of the arena,” says Simon Hess, Team Leader MCR/Playout at MySports.

MySports relies on the six 5G modems embedded in the Haivision Pro transmitter for greater mobility to follow the action. Bonding six cellular networks provided an extremely robust and reliable connectivity for seamless transmission of multiple camera feeds over 4G and 5G networks. Haivision’s Emmy award-winning SST protocol took their live broadcast workflow to the next level by ensuring reliable, high-quality streaming, from the hockey rink to the production studio. Haivision StreamHub, with its powerful set of advanced features such as decoding to SDI, transcoding, return feeds, and two-way intercom, gives them the flexibility to adapt to different production needs.

The new workflow leveraging Haivision Pro and StreamHub has quickly become an essential part of MySports’ broadcasting arsenal. The flexible new production has already paid off, as MySports, with the help of Lang Baranday, has successfully completed two live broadcasts using the cellular transmission solution.

Simon Hess commented on the positive results of leveraging Haivision technology for remote production and low latency video transmission over cellular networks:

“We look forward to continuing this journey and sharing the thrill of hockey with fans everywhere. Stay tuned for more updates as we bring you closer to the ice, one game at a time!”